Products

1. carat tube (HDPE wound B tube)

Product Name: high density polyethylene (HDPE) winding reinforced tube (winding reinforced tube) (hereinafter referred to as carat tube).

Adopt the standard: the tube of carat tube must conform to the GB/T19472.2-2004 type B structure wall tube.

Connection mode: the clam pipe adopts the wound socket type electric melting connection pipe winding material.

Major raw materials: non-toxic and harmless high-density polyethylene (PE), polypropylene (PP) bellows as the top-grade skeleton tube, mixed with certain colorimetric masterbatch for a scientific and uniform proportion.

HDPE high density polyethylene double wall bellows refer to:

Product Name: high density polyethylene (HDPE) double wall bellows (hereinafter referred to as PE double wall bellows);

Adopt standard: PE double wall bellows pipe must conform to GB/T19472.1-2004 type B structure wall pipe.

Connection mode: PE double wall bellows connection mode is tight type socket type filler connection.

Main raw materials: high density polyethylene or rigid polyvinyl chloride resin as the main raw material.

2.1 carat tube production process:

High density polyethylene (HDPE) winding reinforced pipe is made of HDPE in hot melt state by winding forming technology. Before demoulding in hot state, the tube is cooled by rolling air cooling method. The pipe gradually dissipates heat and the wall thickness is uniform. HDPE winding reinforcing pipe is connected by plug-in electric fusion. The two ends of the pipe are processed into sockets and sockets during production, and electric fuse is embedded in the socket. When the pipe is connected, the welding can be completed only by connecting the power supply, and the pipe system can achieve zero leakage.

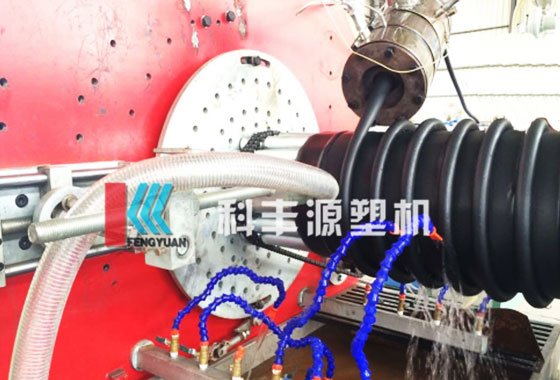

1) Winding: Hot winding process, melted HDPE plain strip and PP-coated circular stiffener winding synchronously on the mold heated to a predetermined temperature.

Winding process of carat tube for carat tube equipment

2) cutting: pipe bearing and inserting ports are processed to standard size.

Cutting of the production process of the carat tube

3) demoulding: the tube is detached from the mold.

Demoulding of the production process of carat tube

4) modification: make the appearance smooth and standard.

The practice of the production process of carat tube

5) electric fuse is buried: electric fuse is embedded in the inner wall of the pipe.

Electric fuse embedding process for the production process of the carat tube

6) product inspection: testing the appearance and size of the products to ensure that the qualified products are out of the factory.

2.2PE double wall bellows production line process flow:

Because PE double-wall bellows are mostly of large caliber specifications and have many raw materials for extrusion molding, twin-screw extruders (parallel or conical twin-screw extruders can be used in general manufacturers), the forming process of PE double-wall bellows mainly passes through three technological processes: tube molding, tube cutting and flaring, as follows

1) tube forming process:

Powder after mixing screen - feeding to Extruder - heating plasticizing to Extruder - shunting to extruder head - compressing to double thin-walled tube - blown by compressed air between module and sizing sleeve - forming inside and outside wall - cooling water sequence but finalized - continuous drawing tube stripping

2) tube cutting process:

Forming machine uniform speed out of the tube - cutting machine fixture clamping and peer - cutting cutter head rotation parallel feed - cutting pipe - cutter head reset - fixture loosening reset - car back to wait for the next command.

Top